$4.95 / mo

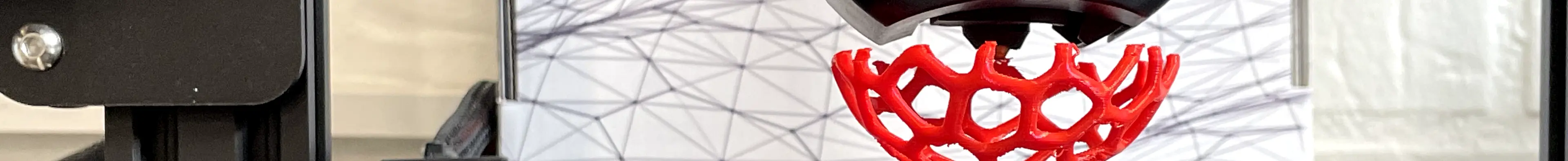

How to 3D print on Bambu Lab with a Chromebook

Start 3D printing on your Bambu Lab with your Chromebook in 6 easy steps

The world of 3D printing continues to evolve, with advancements in hardware and software creating opportunities for makers, hobbyists, and professionals alike. Bambu Lab has emerged as a standout player in this space, known for its high-performance 3D printers that offer unparalleled speed, reliability, and automation.

This all sounds great but what if you are sitting with a Chromebook so downloading Bambu Studio to 3D print is not an option to you?

We have good news for you: REALvision Online is a browser-based slicing software compatible with Bambu models.

Let’s dive into what makes Bambu Lab and REALvision Online such a powerful combination and how you can start your prints in just a few easy steps on any device without downloading any application.

Start 3D printing in 6 easy steps

- Sign up to REALvision Online – 14 days for free! Go to realvisiononline.com and click any of the “get started” buttons. You will be led through a few steps to create your profile. Your 14-day free trial will automatically start. You won’t be charged for this.

2. Choose your Bambu model

When signing up you will first be asked to choose your printer. Right now we support Bambu Lab A1 and Bambu Lab A1 mini. If your machine is not on the list, you can request it on the link here. We are continuously adding more 3D printers, so it is worth it.

3. Start a new print

After creating your profile, you will enter your dashboard, where you can start a new print. When you have made your first print, it is automatically saved and visible as your last printed option.

4. Add your model to the workspace

When starting a new print, you will begin at the workspace area. Here you can see the print bed. You click on the bed or drag your file to upload it. Once your 3D model is on the plate you can easily rotate and scale it by double clicking on the object.

5. Prepare your model for printing

In most cases, you don’t need to set any settings, as the recommended setting will be the best suited. However, if you need support or change in some of the other parameters, you click the settings tab to the right to see the options for your printer.

6. Slice your model to a G-code

When you are happy with the settings, you click the print button in the right corner. You will see that your file is being sliced. After a few seconds, you can see the print time and the amount of filament you need to finish the print.

Just below, you find the download button, click for exporting your G-code file. Once your file is exported it is time to put it on an SD card and insert it into your 3D printer and let the magic happen.

How to change my printer in REALvision Online?

- Log in to REALvision Online

- Go to Profile on the left toolbar

- Choose your printer from the list

- Click on Start printing and you are ready to print!

Happy Printing!

Good to know – General terms related to 3d printing

| 3D printers If you have bought a cheap desktop 3D printer like an FDM printer from Creality but you are not satisfied with the quality of the Creality slicer, then you are not the only one. Historically those printers were sold as kits for 3D printer enthusiasts developing 3D printers themselves such as the RepRap project. Today most 3D printer enthusiasts just want to spend time on printing and not on fixing the 3D printer. This is why slicing and the slicing software is a big part of the success of 3D printing. |

| Filament In Fused Filament Deposition technology, also known as Fused Filament Fabrication, the spool of filament is the material used to build the 3D part by melting the plastic out of the nozzle of the 3D printer. The printer extrudes the filament line by line, layer by layer, by increasing the z-axis, and will build the 3D printed part. |

| STL files STL files are three-dimensional geometries CAD files based on a list of triangles defining the wireframe or the outside shell of the 3D object geometry. There are two types of STL files: they can be ASCII or Binary. The binary STL file format is more size optimized (takes less byte size) while the Ascii STL file format is humanly readable (can be opened in a text editor) and defines the tessellation (list of triangles creating the 3D polygon). To define a triangle the STL file format is a list of triangles made from 3 vertex or 3D vectors. Of course, there are a lot of triangles and they are fairly small so those triangles next to each other define the meshes of your STL 3D print file. |

| CAD / 3D CAD softwares CAD stands for Computer-Aided Design, it is the software part of CAD-CAM solution where you create your 3D designs or more precisely create your 3D models (actual 3D geometries). You can use beginner CAD software like Tinkercad, Google Sketchup, or more advanced CAD software like Autodesk Inventor, using Solidworks, 3DS, Autocad, or even parametric CAD design software like Openscad (script-based CAD software). All CAD software can export a CAD file under different file formats, but without a doubt, the most popular one is the STL file format. |

| GCODE files Gcode files are the files used for 3D printing. There are two types of Gcode files they can be ASCII or Binary, the Ascii files have a bigger file size and are humanly readable, while binary files are not humanly readable. You can easily preview an Ascii Gcode instruction by opening it in a text editor. The file extension or file format is .gcode and is generated from a CAM software usually named a slicer. |

| CAM / Slicer 3D printing software A CAM software in 3D printing is most commonly called a slicer. Slicers are used to create Gcode files. For beginner and intermediate users, you can use online slicers like the online slicer REALvision online; or for expert users, you can use slicers like REALvision Pro, Cura, Ultimaker Cura, Simplify 3D, Creality slicer or Slic3r. A slicer lets you manipulate the STL and then takes a planar cut or cross-section cut of your STL 3D design and automatically generates the movement instruction of your 3D printer (the toolpath) as well as all the repositioning and print strategy of the 3D printer. The filename generated from the slicer or CAM is called a GCODE file and the file format is a .gcode. You can usually simulate the 3D print result by looking at a slicer 3D viewer. |

| A CAD-CAM solution is a combination of creating a 3D design, preparing the manufacturing of the part and ultimately automatically manufacturing the party using an FDM 3D printer or a 3D printing service (like Shapeways, 3Dwarehouse |

| 3D printing Services To print 3D files you can use printing 3D files services such as Shapeways or Materialise. You can upload your STL files and they will ship your 3d prints to your home for a fee. |

| Marketplace If you are not confident in designing your STL 3D files yourself you can download a lot of STL files for free on websites like Thingiverse or Cult 3D where there are thousands of free STL files to choose from. |