$4.95 / mo

How to choose the best slicer for your Creality printer

4 steps to consider when choosing a slicer for your Creality printer

You have bought a creality 3D printer, congratulations!! You are on your way to become a real Maker.

Now comes the time to get successful prints and the 3D printing software you will use (the slicer) will be a big part of this. Most people directly jump into professional slicers like the Creality slicer, Cura, or Simplify3D. But those software are not easy to use and have a pretty steep learning curve which in the end discourages people from becoming makers.

In short, the best slicer for a Creality printer is an easy-to-use slicer with great print quality. Follow the four steps to be successful:

Update: New Creality printers are available in REALvision Online!

The following models have been added after popular request:

Creality Ender 3 V3 SE

Creality Ender 3 V3 KE

Creality CR-10 SE

Creality K1

Creality K1 MAX

1. Go for ease of use and progressive learning curve

Creality 3D printers are the entry point printers, so you certainly are starting with 3D printing and are on your way to becoming a maker. For it to be fun you need to carefully choose the slicing software you want to use. Some slicers are very powerful but what is power without control..? If you are not an expert in 3D printing your chances of taking advantage of this are low. So no matter what slicer you choose, look at the ease of use and the way to progressively learn to use its power.

2. Start using an easy-to-use online slicer

An online slicer is a good way to get started quickly with very little effort, without having to download and install anything on your computer, or even better, you are able to use it on other devices than your PC such as phone or tablet. Of course, you need to find one which gives good print quality. You can for example try an online slicer like REALvision Online for free and quickly get successful prints.

3. Start with simple 3D object shapes

Choose your object carefully. An easy object is which doesn`t need a lot of support or changing any other settings such as orientation or size. But how do we know if an object needs support or not?

If the object has a lot of parts that are overhanging the plate, so it is not touching the build plate on many points, therefore would be printed in the air, which requires support. If the object lays on the build plate with most of its surface, it will not require support.

Let`s see some examples. The wall decoration on the picture below does not require support as the object is flat and can be completely laid down on the build plate with its entire surface.

While this other object in the picture below has a lot of overhanging parts, so it needs support at each place where it is not touching the build plate.

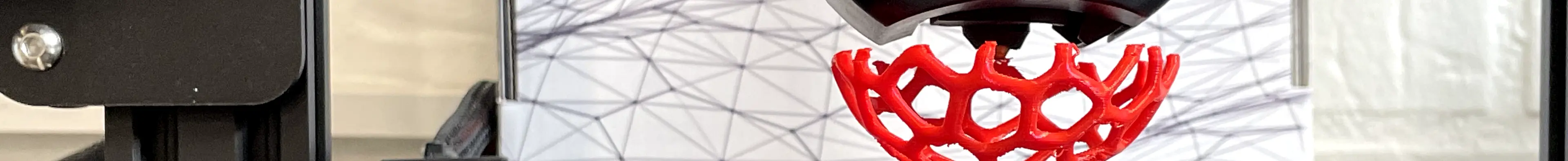

Some models are specifically designed not to use support such as the one in the picture below. In this case, support would be limiting the function of the object as the body needs to be able to move in many directions.

You can find these 3D models and many more in STL format for free on Thingiverse, so you just need to quickly convert it with REALvision Online to Gcode, so your printer can read it and you are ready to print! You can also get some inspiration for what to print first from this article.

4. Increase slowly the object complexity

As you become a real maker, start finding more complex objects, or start designing your own models. As a beginner, the different CAD softwares might not be easy to use. But it shouldn`t stop you to make your own ideas real. With intuitive modeling programs like Tinkercad (or FreeCAD) you can create your 3D models from scratch for free without any previous design experience.

In conclusion, the best slicer for a Creality printer is an easy-to-use slicer that helps you to get great print quality. I hope you find these tips useful and you will have successful prints and a lot of fun!

Good to know – General terms related to 3D printing

| 3D printers If you have bought a cheap desktop 3D printer like an FDM printer from Creality but you are not satisfied with the quality of the Creality slicer, then you are not the only one. Historically those printers were sold as kits for 3D printer enthusiasts developing 3D printers themselves such as the reprap project. Today most 3D printer enthusiasts just want to spend time on printing and not on fixing the 3D printer. This is why slicing and the slicing software are a big part of the success of 3D printing. |

| Filament In Fused Filament Deposition technology, also known as Fused Filament Fabrication, the spool of filament is the material used to build the 3D part by melting the plastic out of the nozzle of the 3D printer. The printer extrudes the filament line by line, layer by layer, by increasing the z axis, and will build the 3D printed part. |

| STL files STL files are three-dimensional geometries CAD files based on a list of triangles defining the wireframe or the outside shell of the 3D object geometry. There are two types of STL files: they can be ASCII or Binary. The binary STL file-format is more size optimized (takes less byte size) while the Ascii STL file-format is human readable (can be opened in a text-editor) and defines the tessellation (list of triangles creating the 3D polygon). To define a triangle the STL file format is a list of triangles made from 3 vertex or 3D vectors. Of course, there are a lot of triangles and they are fairly small so those triangles next to each other define the meshes of your STL 3D print file. |

| CAD / 3D CAD softwares CAD stands for Computer Aided Design, it is the software part of CAD-CAM solution where you create your 3D designs or more precisely create your 3D models (actual 3D geometries). You can use beginner CAD software like Tinkercad, Google Sketchup, or more advanced CAD software like Autodesk Inventor, using Solidworks, 3DS, Autocad, or even parametric CAD design software like Openscad (script-based CAD software). All CAD software can export a CAD file under different file formats, but without a doubt, the most popular one is the STL file format. |

| GCODE files Gcode files are the files used for 3D printing. There are two types of Gcode files they can be ASCII or Binary, the Ascii files have a bigger file size and are human readable, while binary files are not human readable. You can easily preview an Ascii Gcode instruction by opening it in a text editor. The file extension or file format is .gcode and is generated from a CAM software usually named a slicer. |

| CAM / Slicer 3D printing software A CAM software in 3D printing is most commonly called a slicer. Slicers are used to create Gcode files. For beginner and intermediate users, you can use online slicers like the online slicer REALvision online; or for expert users, you can use slicers like REALvision Pro, Cura, Ultimaker Cura, Simplify 3D, Creality slicer or Slic3r. A slicer lets you manipulate the STL and then takes a planar cut or cross-section cut of your STL 3D design and automatically generates the movement instruction of your 3D printer (the toolpath) as well as all the repositioning and print strategy of the 3D printer. The filename generated from the slicer or CAM is called a GCODE file and the file-format is a .gcode. You can usually simulate the 3D print result by looking at a slicer 3D viewer. |

| A CAD-CAM solution which is a combination of creating a 3D design, preparing the manufacturing of the part and ultimately automatically manufacturing the party using an FDM 3D printer or a 3D printing service (like Shapeways, 3Dwarehouse |

| 3D printing Services To print 3D files you can use printing 3D files services such as Shapeways or Materialise. You can upload your STL files and they will ship your 3d prints to your home for a fee. |

| Marketplace If you are not confident in designing your STL 3D files yourself you can download a lot of STL files for free on websites like Thingiverse or Cult 3D where there are thousands of free STL files to choose from. |